Transform Manufacturing with Intelligent AI

Discover how leading manufacturers are leveraging AI technologies to optimize operations, reduce costs, and drive unprecedented efficiency across the production lifecycle.

The Future of Manufacturing is Intelligent

Manufacturing is undergoing a profound transformation driven by artificial intelligence. From predictive maintenance that prevents costly downtime to computer vision systems that ensure perfect quality, AI is revolutionizing every aspect of production.

Our curated collection of manufacturing AI case studies showcases real-world implementations across seven key technology verticals, helping you identify the right solutions for your specific challenges.

- Real-world implementation examples

- Measurable ROI and outcomes

- Diverse industry applications

- Technology stack insights

Manufacturing AI Technology Verticals

Explore our comprehensive coverage of AI applications in manufacturing, organized by technology vertical to help you find relevant solutions.

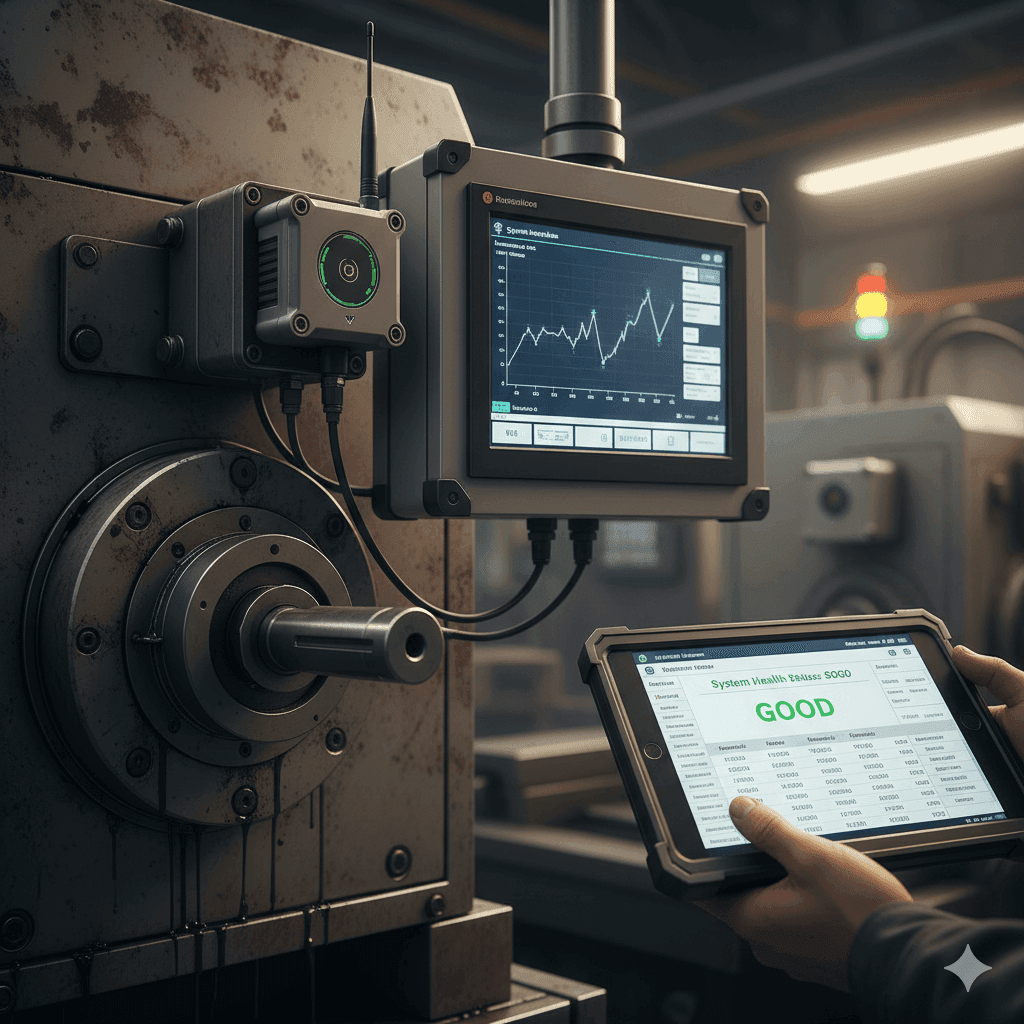

Predictive Maintenance & Asset Reliability

Transform equipment maintenance from reactive to proactive with AI-powered predictive analytics.

Leverage machine learning algorithms to analyze sensor data, vibration patterns, and historical maintenance records to predict equipment failures before they occur. Reduce unplanned downtime by up to 50% and extend asset lifespan significantly.

Key Benefits

- Reduce unplanned downtime by 30-50%

- Extend equipment lifespan by 20-40%

- Lower maintenance costs by 10-25%

Common Use Cases

- Rotating equipment monitoring

- Vibration analysis

- Thermal imaging analysis

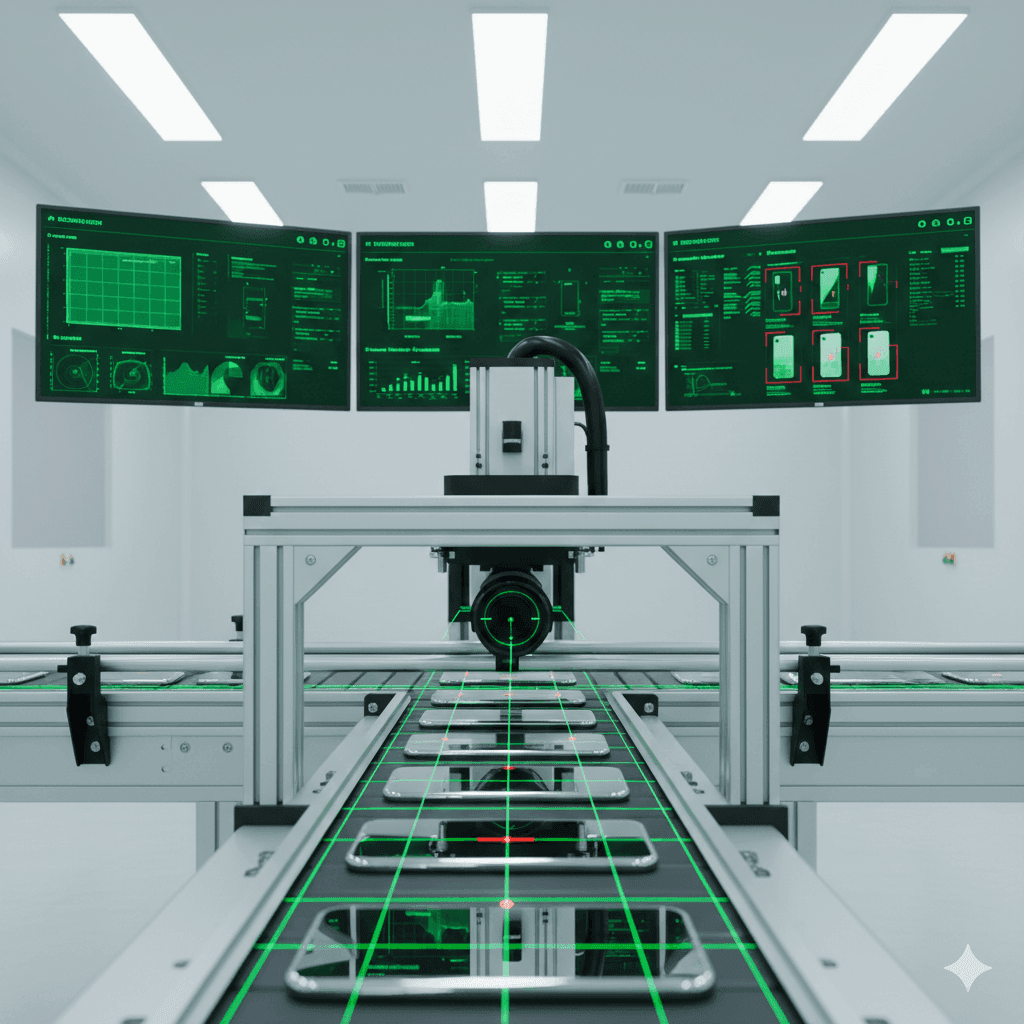

Quality Inspection & Computer Vision

Automate visual inspection with AI-powered computer vision for consistent, high-speed quality control.

Deploy deep learning models trained on thousands of product images to detect defects, anomalies, and quality deviations in real-time. Achieve inspection accuracy rates exceeding 99% while dramatically increasing throughput.

Key Benefits

- Achieve 99%+ defect detection accuracy

- Reduce inspection time by 80%

- Eliminate human error in repetitive tasks

Common Use Cases

- Surface defect detection

- Dimensional measurement verification

- Assembly verification

Process Optimization & Analytics

Optimize manufacturing processes with data-driven insights and real-time analytics.

Harness the power of advanced analytics and machine learning to identify inefficiencies, optimize parameters, and continuously improve manufacturing processes. Drive operational excellence through data-driven decision making.

Key Benefits

- Increase production yield by 5-15%

- Reduce energy consumption by 10-20%

- Minimize waste and scrap rates

Common Use Cases

- Production scheduling optimization

- Energy management

- Yield optimization

Supply Chain Optimization & Forecasting

Build resilient supply chains with AI-powered demand forecasting and inventory optimization.

Utilize advanced forecasting algorithms that consider multiple variables including market trends, seasonality, and external factors to optimize inventory levels, reduce stockouts, and improve supplier management.

Key Benefits

- Improve forecast accuracy by 20-50%

- Reduce inventory carrying costs by 15-30%

- Minimize stockouts and overstock situations

Common Use Cases

- Demand forecasting

- Inventory optimization

- Supplier risk assessment

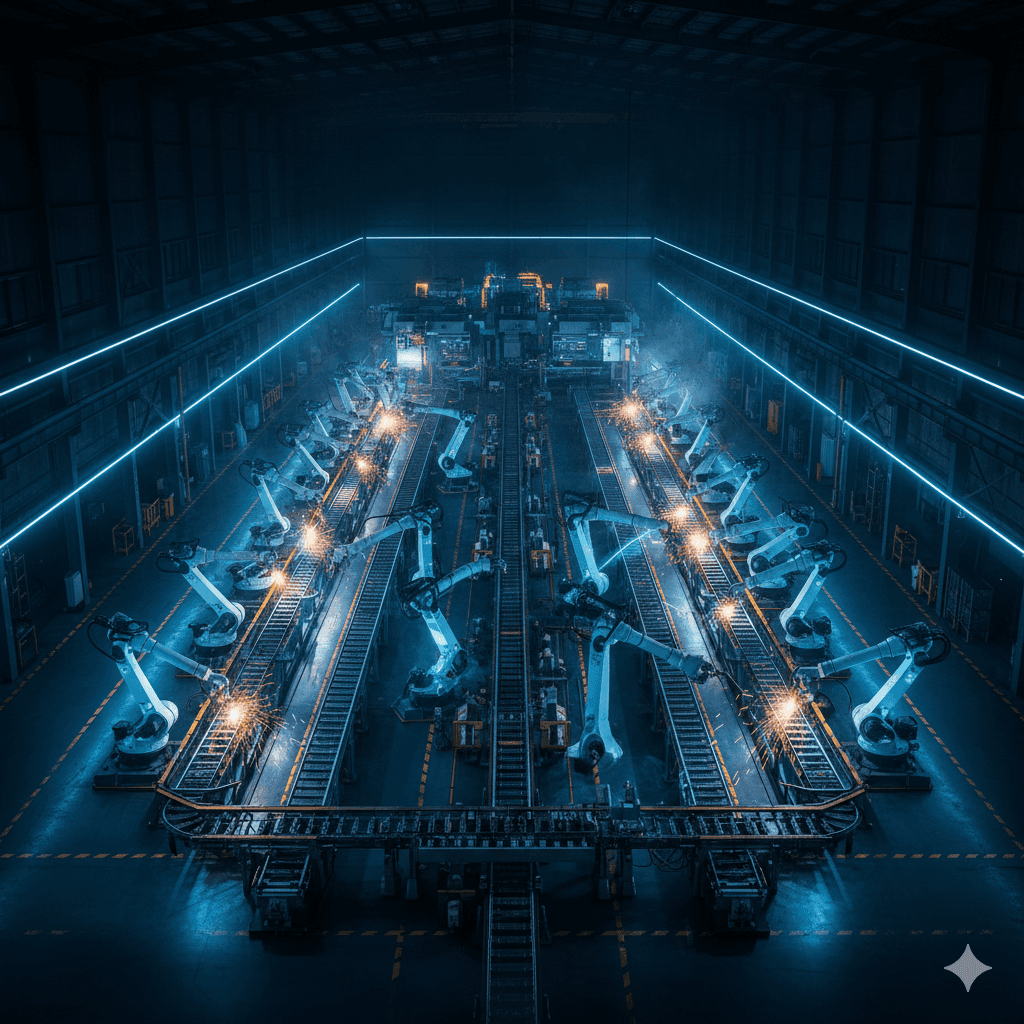

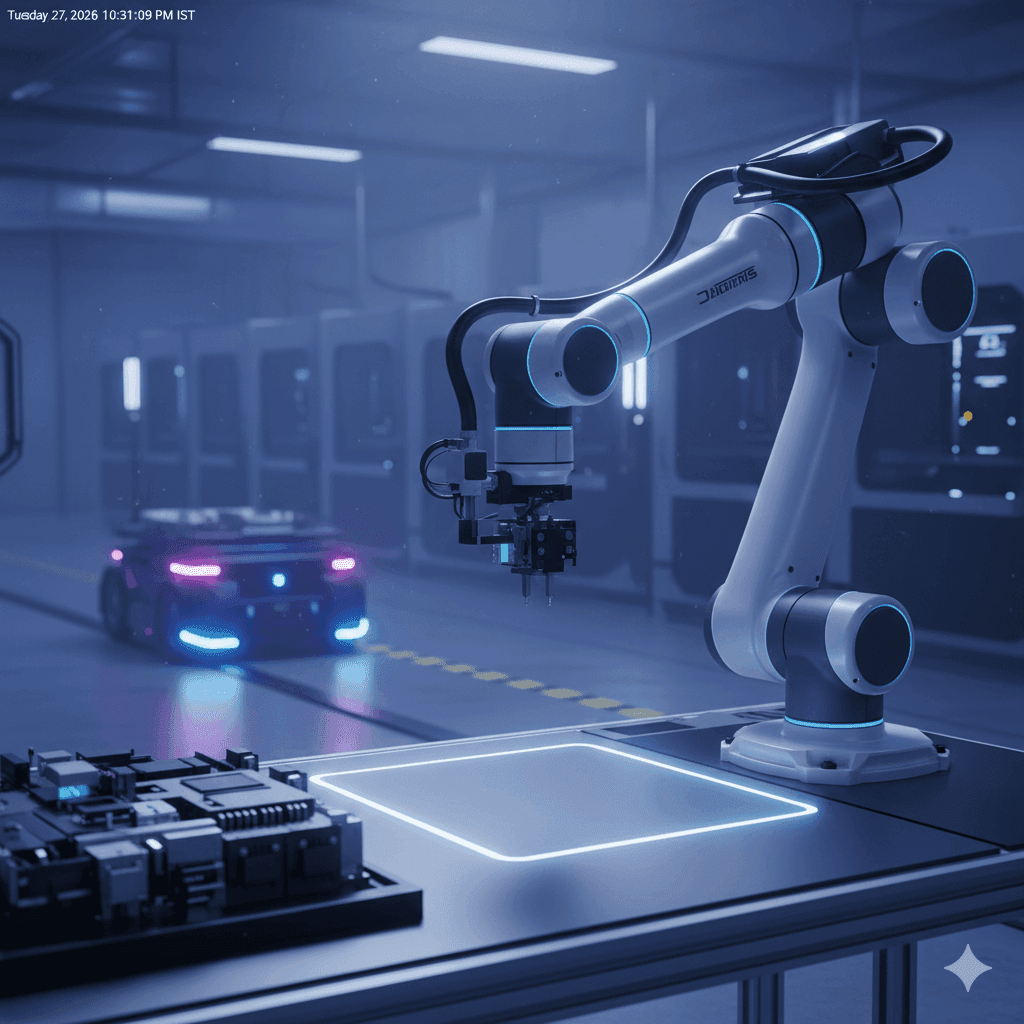

Autonomous Operations & Robotics

Deploy intelligent automation and robotics for safer, more efficient manufacturing operations.

Implement AI-powered autonomous systems including collaborative robots (cobots), autonomous mobile robots (AMRs), and intelligent automation solutions that work alongside human operators to enhance productivity and safety.

Key Benefits

- Increase production throughput by 25-40%

- Reduce workplace injuries significantly

- Enable 24/7 operations capability

Common Use Cases

- Material handling automation

- Collaborative assembly operations

- Autonomous guided vehicles (AGVs)

Generative AI for Smart Manufacturing

Accelerate innovation with generative AI for design, documentation, and workflow automation.

Leverage large language models and generative AI to automate documentation, generate design variations, create training materials, and streamline communication across manufacturing operations.

Key Benefits

- Accelerate product design cycles by 30-50%

- Automate technical documentation

- Enhance knowledge management

Common Use Cases

- Generative design optimization

- Automated report generation

- Intelligent chatbots for operators

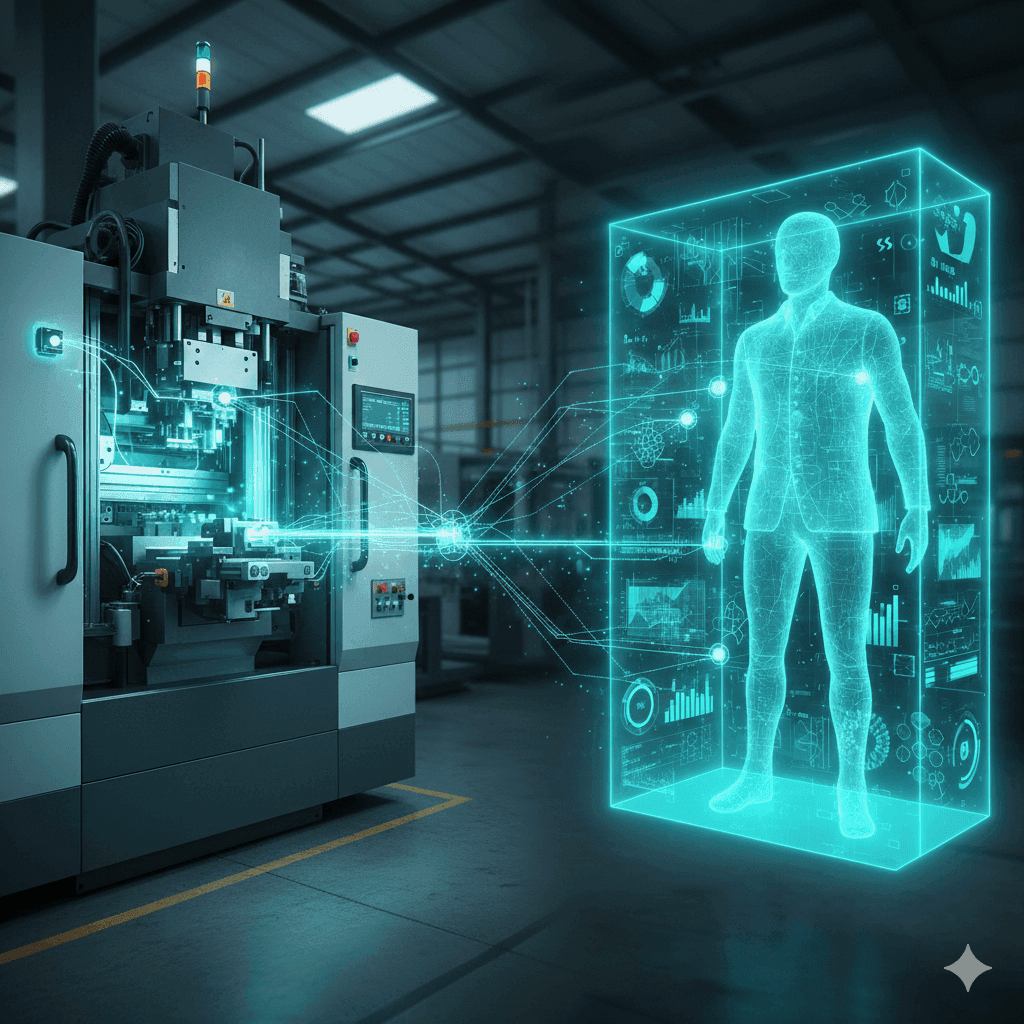

Digital Twin & Industrial AI

Create virtual replicas of physical assets for simulation, monitoring, and optimization.

Build comprehensive digital twins that mirror your physical manufacturing environment, enabling real-time monitoring, what-if scenario analysis, and continuous optimization without disrupting actual operations.

Key Benefits

- Reduce commissioning time by 20-30%

- Enable risk-free experimentation

- Improve operational visibility

Common Use Cases

- Virtual commissioning

- Production simulation

- Real-time asset monitoring

Ready to Transform Your Manufacturing Operations?

Explore our case studies to discover how leading manufacturers are achieving breakthrough results with AI implementation.